In the fall of 2006 I acquired a 1954 Dodge Power Wagon truck while out driving the back roads of Vermont, route 109 to be exact. A rusty old truck next to the road caught my eye. The owner happened to be mowing his lawn so I stopped . I must have been blinded by the Rust Flu for I could not see how much work this truck really needed. I seemed to miss the broken frame and the fact that two cylinder walls were cracked. The head to the 230 ci motor was resting on the front seat. Someone had cut the last two inches off the bed with a torch. Inhabitants plagued the cab like a condo running amuck, five mouse nests, two bees nest and a dead snake, biohazard site for sure. The nests rotted out the wiper cowl area and lower doors. This old wood truck had its share of running into objects, bed sides bowed out no doubt from being overloaded. Previous owners must have been amateurs at throwing wood and used the back of the cab as a backboard. The Rust Flu was hard at work, swaying any rational thought, letting passion and desire overrun common sense. Gazing googly eyed into pitted headlight buckets. Trying to justify the legitimacy of restoration or delegate the vehicle to mere parts car status.

In the fall of 2006 I acquired a 1954 Dodge Power Wagon truck while out driving the back roads of Vermont, route 109 to be exact. A rusty old truck next to the road caught my eye. The owner happened to be mowing his lawn so I stopped . I must have been blinded by the Rust Flu for I could not see how much work this truck really needed. I seemed to miss the broken frame and the fact that two cylinder walls were cracked. The head to the 230 ci motor was resting on the front seat. Someone had cut the last two inches off the bed with a torch. Inhabitants plagued the cab like a condo running amuck, five mouse nests, two bees nest and a dead snake, biohazard site for sure. The nests rotted out the wiper cowl area and lower doors. This old wood truck had its share of running into objects, bed sides bowed out no doubt from being overloaded. Previous owners must have been amateurs at throwing wood and used the back of the cab as a backboard. The Rust Flu was hard at work, swaying any rational thought, letting passion and desire overrun common sense. Gazing googly eyed into pitted headlight buckets. Trying to justify the legitimacy of restoration or delegate the vehicle to mere parts car status.

Why a Power Wagon? Just a work truck, a tractor with a cab, born out of the World War II WC trucks. My interest in vehicles isn’t just the flow of the lines, blending of panels, 50 shades of gray, horsepower, and chrome bumpers, its the history of the vehicle, stories, development and researching parts manuals and shop manuals. This truck was legendary for its toughness and durability like the men who used it. From combat to farms both environments demanding, it answered the call. Restoration started with disassembly, the endless labeling & bagging. The parts list continued to grow. While tracking down parts, I met some great people and contacts, this is the other joy of our hobby. The down side is the endless sandblasting and expense. Many restorations fail at this point and keeping the spark and drive alive can be tough. I stayed involved by attending rallies and online forums, gaining knowledge I needed for the restoration. Each vehicle has its unique quirks, you know what I mean. Before the Shelburne show I had only driven a Power Wagon once before, an M37 military equivalent, it had a synchromesh transmission and mine doesn’t. It left an impression of crude but purpose built machine, rugged and overbuilt. I was hooked. Hooked enough to endure 10 years worth of, on and off again restoration effort. I kept pecking away at it. Locating a good frame, salvageable block and a lot of bed pieces. A tough process for a vehicle that the aftermarket reproduction companies tend to ignore because there isn’t a healthy profit in it. I was use to Mustangs, parts available anytime, anywhere and reasonably priced,…. Down to every nut and bolt. I found Power Wagons have a true and devoted following. Make a few connections and used parts and advice can be found. So I set monthly goals, little tasks and kept working at it. March of 2015 I had the bed done, April wiring and May the brakes. The Shelburne Show was the maiden voyage with the truck, still not complete, but I attained the goal. I do all my own work except for a few select things, I’ll be the first to admit “jack of all trades master of none”. It’s a battle when everything is twice as heavy and damaged. The old truck was well received and many nice comments. People stopped to tell stories of their Dodge experiences. Timber handlers, farmers, uncles, dads and Veterans all had something to say about a Power Wagon, invoking memories of the past. Listening to the stories only added to the event. Now, if I could only manage more than 35 mph, or as I like to say” I can go anywhere in the world at 30MPH……… VIVA LA POWERWAGON…

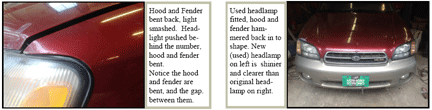

Recently my wife was driving the kids to school in the Subaru when the truck in front of her stopped. She didn’t. The impact smashed the left headlight assembly, and bent the hood, fender and radiator support. The headlight also contains the directional and running lamp. The hood was bent enough to separate the skin from the frame.

Recently my wife was driving the kids to school in the Subaru when the truck in front of her stopped. She didn’t. The impact smashed the left headlight assembly, and bent the hood, fender and radiator support. The headlight also contains the directional and running lamp. The hood was bent enough to separate the skin from the frame. Please email all inquiries to:

Please email all inquiries to:  I recently noticed the airflow on my Subaru’s heater was weak on one of the many below zero mornings. I remembered this car had a cabin air filter, and I know I have never replaced it. The owners manual states the filter should be replaced annually, or every 15 thousand miles, depending on the conditions the car is driven in. This car has 230,000 miles on it, and this was the factory cabin filter, I had never changed it. I live on a very dusty dirt road, so I should theoretically be changing the filter more often.

I recently noticed the airflow on my Subaru’s heater was weak on one of the many below zero mornings. I remembered this car had a cabin air filter, and I know I have never replaced it. The owners manual states the filter should be replaced annually, or every 15 thousand miles, depending on the conditions the car is driven in. This car has 230,000 miles on it, and this was the factory cabin filter, I had never changed it. I live on a very dusty dirt road, so I should theoretically be changing the filter more often. This month, I am talking about my tool box, or rather, my tool boxes. I have three tool boxes, lined up to each other side by side. On the farthest right side I have my first tool box. It is an inexpensive Craftsman tool box that I have had since I was a young teenager. For years this sat next to my work bench. Whatever did not fit in this box or the drawers of my work bench was hung up on the garage walls. This tool box now holds tools that I seldom use. These tools include things like my air conditioning tools, brake tools, and engine rebuilding tools. Some tools sit in this tool box for a year or more with no use.

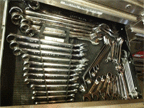

This month, I am talking about my tool box, or rather, my tool boxes. I have three tool boxes, lined up to each other side by side. On the farthest right side I have my first tool box. It is an inexpensive Craftsman tool box that I have had since I was a young teenager. For years this sat next to my work bench. Whatever did not fit in this box or the drawers of my work bench was hung up on the garage walls. This tool box now holds tools that I seldom use. These tools include things like my air conditioning tools, brake tools, and engine rebuilding tools. Some tools sit in this tool box for a year or more with no use. No toolbox should be without sockets too. I have both 6 point and 12 point sockets, in both standard and deep socket. I have these socket sets in Metric, SAE and BSF (British Whitworth). I have these sockets in 1/4″, 3/8″ and 1/2″. All of my 1/4″ sockets have their own drawer, as do my 3/8″, 1/2″ and 3/4″ sockets.

No toolbox should be without sockets too. I have both 6 point and 12 point sockets, in both standard and deep socket. I have these socket sets in Metric, SAE and BSF (British Whitworth). I have these sockets in 1/4″, 3/8″ and 1/2″. All of my 1/4″ sockets have their own drawer, as do my 3/8″, 1/2″ and 3/4″ sockets. I have an assortment of specialty tools that I have purchased from auto parts stores, these were usually tools that I needed to finish a project.

I have an assortment of specialty tools that I have purchased from auto parts stores, these were usually tools that I needed to finish a project.

Trailer tires are quite different from traditional passenger car and truck tires. Trailer tires are not designed for either tractive effort or steering adhesion. The tread design is not optimized for ride comfort or noise reduction. Most importantly, the side walls are designed to reduce trailer sway and provide optimum control.

Trailer tires are quite different from traditional passenger car and truck tires. Trailer tires are not designed for either tractive effort or steering adhesion. The tread design is not optimized for ride comfort or noise reduction. Most importantly, the side walls are designed to reduce trailer sway and provide optimum control. This summer I decided it was time to figure out what was wrong with the car and fix it. I found a sunken carburetor float in the rear carburetor, a torn diaphragm in the front carburetor, a bad fuel pump and a dead battery. Once I got these issues sorted out, I began to tune the car and get it running again. It soon became apparent that there was an issue with the brakes. Both front and rear brakes were dragging, and the pedal did not feel right. I know that the brake fluid has not been changed in at least 15 years. When I removed the caps to inspect the brake fluid, I found a nasty surprise. We all know that brake fluid absorbs moisture. Due to some spring flooding this year, the building the car was stored in, had several inches of standing water on the floor of the garage.

This summer I decided it was time to figure out what was wrong with the car and fix it. I found a sunken carburetor float in the rear carburetor, a torn diaphragm in the front carburetor, a bad fuel pump and a dead battery. Once I got these issues sorted out, I began to tune the car and get it running again. It soon became apparent that there was an issue with the brakes. Both front and rear brakes were dragging, and the pedal did not feel right. I know that the brake fluid has not been changed in at least 15 years. When I removed the caps to inspect the brake fluid, I found a nasty surprise. We all know that brake fluid absorbs moisture. Due to some spring flooding this year, the building the car was stored in, had several inches of standing water on the floor of the garage. So, what makes water pump grease different than conventional chassis grease? Depending on the grease, it is either a grease that won’t be washed away by water, or a water soluble grease that will wash away and dissolve in water preventing a blockage in the cooling system.

So, what makes water pump grease different than conventional chassis grease? Depending on the grease, it is either a grease that won’t be washed away by water, or a water soluble grease that will wash away and dissolve in water preventing a blockage in the cooling system.