This month’s question comes from Wendell Nobel:

Dave, I would love to read a little dissertation on automotive paints. I recall a day when GM cars were all painted with acrylic lacquer and Fords were acrylic enamel. Now we have polyurethane base coat with clear coat, single stage urethane and even some water based stuff. What is an antique car guy to make of it all? Should we use what was on the car when new or get up to date? Will environmental laws make the question moot?

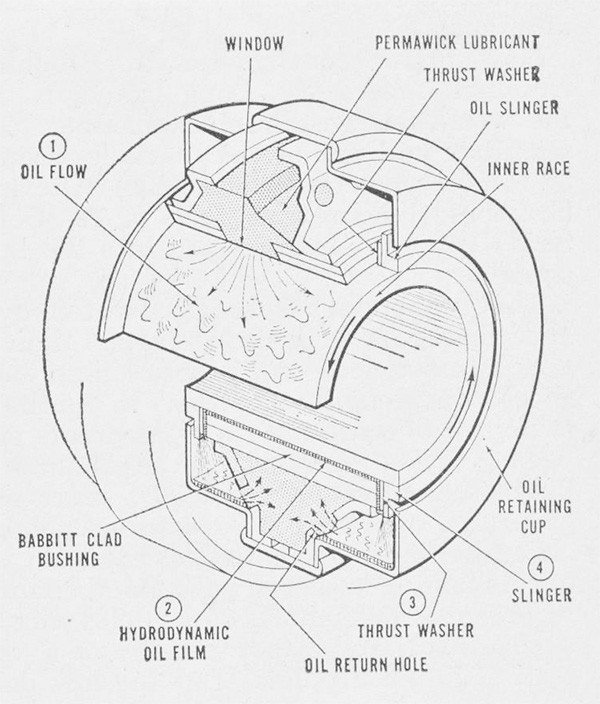

Let me first briefly explain the history of automotive paints. The early autos were painted with the same paint people had been painting carriages with for years. There was no “automotive” paint. Not paint in the traditional sense we think of when we talk about paint today. Early paint was basically linseed oil and a binder, with pigment, or crude shellac. This paint was applied with a brush and took a long time to dry. These paints were not very durable, often literally falling off the metal in a year or two. These finishes offered very little U/V protection and broke down quickly.

Let me first briefly explain the history of automotive paints. The early autos were painted with the same paint people had been painting carriages with for years. There was no “automotive” paint. Not paint in the traditional sense we think of when we talk about paint today. Early paint was basically linseed oil and a binder, with pigment, or crude shellac. This paint was applied with a brush and took a long time to dry. These paints were not very durable, often literally falling off the metal in a year or two. These finishes offered very little U/V protection and broke down quickly.

The biggest challenge with producing the Model T Ford and other early cars was the time and space needed to paint cars. The parts were laid out on the floor and took days to dry. This bottle neck in the production was a huge problem.

Nitrocellulose Lacquer paint was developed to alleviate the time/space problem. Nitrocellulose Lacquer paint is made from the nitration of cellulose plants (boiling down plant fibers and mixing with nitric acid). This is also how celluloid film was made. The solvents evaporate from the paint, leaving a glossy durable paint finish. These paints need to be “rubbed out” to produce a shine. This paint does not “cure” and will return to a liquid state when solvents are applied. A popular early nitrocellulose lacquer paint was DuPont “Duco” paint.

Nitrocellulose Lacquer dominated the automotive paint market from the early 1920s well in to the 1950’s when it was displaced by Acrylic Lacquer, a synthetic polymer acrylic resin based lacquer. Acrylic Lacquer dried quickly, however, still needed to be buffed to a high gloss.

Enamel paints used enamel resins. This type of paint takes much longer to dry than lacquer and actually dries in two steps. First, the enamel reducer evaporates and the paint becomes solid. Next, the resin oxidizes when it reacts to the air. This is why the new finish cannot be waxed for 30 days after application. The enamel paints dry to a hard, glossy finish and do not need the rubbing out as lacquer needs. The drying of enamel paints could be accelerated by the use of a baking oven.

Enamel paints used enamel resins. This type of paint takes much longer to dry than lacquer and actually dries in two steps. First, the enamel reducer evaporates and the paint becomes solid. Next, the resin oxidizes when it reacts to the air. This is why the new finish cannot be waxed for 30 days after application. The enamel paints dry to a hard, glossy finish and do not need the rubbing out as lacquer needs. The drying of enamel paints could be accelerated by the use of a baking oven.

Enamel paints required the need for clean spray booths. The paint took so much longer to dry than lacquer paints; the finish was much more susceptible to damage from debris before it dried.

Lacquer and enamel paints were much more durable than the paint they replaced, but still offered minimal protection against U/V light and corrosion.

Lacquer and enamel paints are very unstable, and begin a color shift almost immediately. This fact makes them very hard to color match. People go to great lengths to match original colors. Unfortunately, the reality is the “original” color was so unstable there really is no true original color. Two cars painted the same color at the same time would not match each other after a few years time.

Today’s urethane paints offer much more protection than the lacquer and enamel paints they replaced. Urethane paint cures in three steps: evaporation of the reducer, oxidation of the resin and an irreversible chemical reaction between the resin and the isocyanate catalyst. Urethane paints began to be widely used in the late 1980s.

Base/clear paints offer even more protection. The color coat is completely buried under a protective clear coat. The clear coat provides the gloss in the paint.

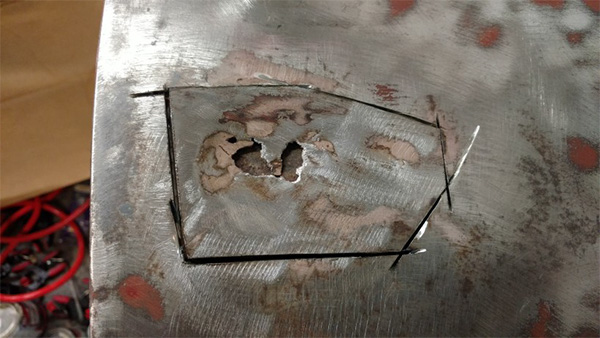

Modern catalyzed urethane primers and paints offer a finish that can easily last the life of the car. I have found bare metal painted with epoxy primer and top coated with urethane paint offered very effective protection against corrosion.

So, what is an old car person to do?

So, what is an old car person to do?

Nitrocellulose Lacquer is almost impossible to find today. It also cracks easily, and will return to a liquid when exposed to solvents. Lacquer requires sanding and buffing to get a good gloss. Enamel paints are harder to paint, do not have stable color pigments, and oxidize quickly.

An authentic restoration would require the use of the original type of paint. Modern urethane paints do not have the same gloss and color hue; however, they are much more stable. Enamel paints are still available, although somewhat hard to get. Given the time and expense involved in a proper paint job, you have to consider the service life of the paint. Do you want to paint it again in 10 or 15 years?

Modern urethane paints are very forgiving to paint, and last a long time. Modern urethane finishes have a fantastic shine, and require minimal maintenance.

If you want to exactly duplicate an original car, you may want to consider a period correct paint. If you want the best shine, great corrosion protection and minimal maintenance you probably want a modern catalyzed urethane paint. I guess it is ultimately up to the user to decide which way to go.

Just to complicate things, there are new paints being used now which are replacing urethane paints. Waterborne paints are now on the market. Waterborne paints do not have the Volatile Organic Compound exposure of urethane paints. Use of waterborne paint, is being mandated slowly, due to environmental concerns.

Let me first briefly explain the history of automotive paints. The early autos were painted with the same paint people had been painting carriages with for years. There was no “automotive” paint. Not paint in the traditional sense we think of when we talk about paint today. Early paint was basically linseed oil and a binder, with pigment, or crude shellac. This paint was applied with a brush and took a long time to dry. These paints were not very durable, often literally falling off the metal in a year or two. These finishes offered very little U/V protection and broke down quickly.

Let me first briefly explain the history of automotive paints. The early autos were painted with the same paint people had been painting carriages with for years. There was no “automotive” paint. Not paint in the traditional sense we think of when we talk about paint today. Early paint was basically linseed oil and a binder, with pigment, or crude shellac. This paint was applied with a brush and took a long time to dry. These paints were not very durable, often literally falling off the metal in a year or two. These finishes offered very little U/V protection and broke down quickly. Enamel paints used enamel resins. This type of paint takes much longer to dry than lacquer and actually dries in two steps. First, the enamel reducer evaporates and the paint becomes solid. Next, the resin oxidizes when it reacts to the air. This is why the new finish cannot be waxed for 30 days after application. The enamel paints dry to a hard, glossy finish and do not need the rubbing out as lacquer needs. The drying of enamel paints could be accelerated by the use of a baking oven.

Enamel paints used enamel resins. This type of paint takes much longer to dry than lacquer and actually dries in two steps. First, the enamel reducer evaporates and the paint becomes solid. Next, the resin oxidizes when it reacts to the air. This is why the new finish cannot be waxed for 30 days after application. The enamel paints dry to a hard, glossy finish and do not need the rubbing out as lacquer needs. The drying of enamel paints could be accelerated by the use of a baking oven. So, what is an old car person to do?

So, what is an old car person to do?