Dear Dave, I have a ’28 Hupmobile that is not coming out of it’s winter cocoon too well!

It has gas, I have spark, & I believe we’ve got air, but maybe you can help me figure out what I can do to make it run. I have charged the battery. When I depress the starter toe switch it engages the starter & occasionally it “catches” and runs and then sputters out. My Hup manual says to bring a car that’s sat idle for a while back to life, it is recommended to put 2 tablespoons of oil down each cylinder (take plug out, pour oil in, put plug back on), this will create vacuum so carb can suck gas from the vacuum system (which worked like a charm last year). And it worked ok for a little while this year, but after it burns out the oil, the car doesn’t stay running.

I tried spraying starter fluid down the throat of the carb….it worked for a little duration, but didn’t stay running. When I gave it more gas to get the idle up, it would sputter and die. I checked to see if we’re getting gas from the tank, I did this by disconnecting the hose that comes off the vacuum canister on the firewall. With the spigot open, we get plenty of gas out of the canister. I also unscrewed the strainer plug (this car has a Stromberg sf-2 carb) off the top of the carb to see if we had gas there, oh, we’ve got plenty of gas there…..Could it be the float is sticking or is stuck or is sunk in the carb?

So I’m at a loss. There seems to be a screw on the bottom of the carb….perhaps I can unscrew that to release all the gas in the carb & it will move the internal debris so the float might work better? Or should I just remove the whole carburetor and carefully take it apart, clean all the bits and pieces and reassemble it? Any insights would be helpful.

Respectfully, Chris Chartier

Chris,

It sounds like you have done enough trouble shooting to trace the problem to the carburetor. You are getting fuel, you are getting spark, and you have enough compression to start the engine.

It is very common for a carburetor to be gummed up after being in storage. You could also have a float issue. The float could either be sunken or stuck. The needle valve could also be sticking. The first thing I would check is the float level. You can easily tell if the float has a hole in it. It will not rise to the top of the float bowl, and when shaken you can hear and feel gas in it. If the float has a hole in it, you can also remove it and usually see gasoline weeping out of a crack or a hole. If you find a crack or a hole, and the float is brass, you can temporarily fix it with J.B Weld, or carefully solder it with a soldering iron to make it function until you get a new float.

If the needle valve is sticking, the float will float, but the needle valve will not shut off. This will cause the carb to flood out.

If everything checks out with the float and the needle valve, I would suspect the main jet next. If the jet has any gum, varnish or debris in it, it will not allow the fuel to atomize and the engine will not run. It is common to find small particles in the bottom of the float bowl, and often in the jet too. I would remove the jet and visually inspect it. Clean the jet and the bottom of the float bowl out really well with carburetor cleaner, then blow the jet out with compressed air.

You may need to obtain a gasket set or a carb rebuild kit to clean the carburetor and get it to function well again.

Please email all inquiries to: Dave

Please email all inquiries to: Dave

or snail mail

32 Turkey Hill Road

Richmond VT 05477

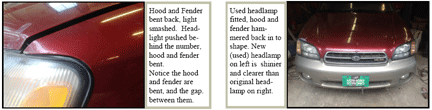

Recently my wife was driving the kids to school in the Subaru when the truck in front of her stopped. She didn’t. The impact smashed the left headlight assembly, and bent the hood, fender and radiator support. The headlight also contains the directional and running lamp. The hood was bent enough to separate the skin from the frame.

Recently my wife was driving the kids to school in the Subaru when the truck in front of her stopped. She didn’t. The impact smashed the left headlight assembly, and bent the hood, fender and radiator support. The headlight also contains the directional and running lamp. The hood was bent enough to separate the skin from the frame. I recently noticed the airflow on my Subaru’s heater was weak on one of the many below zero mornings. I remembered this car had a cabin air filter, and I know I have never replaced it. The owners manual states the filter should be replaced annually, or every 15 thousand miles, depending on the conditions the car is driven in. This car has 230,000 miles on it, and this was the factory cabin filter, I had never changed it. I live on a very dusty dirt road, so I should theoretically be changing the filter more often.

I recently noticed the airflow on my Subaru’s heater was weak on one of the many below zero mornings. I remembered this car had a cabin air filter, and I know I have never replaced it. The owners manual states the filter should be replaced annually, or every 15 thousand miles, depending on the conditions the car is driven in. This car has 230,000 miles on it, and this was the factory cabin filter, I had never changed it. I live on a very dusty dirt road, so I should theoretically be changing the filter more often. This month, I am talking about my tool box, or rather, my tool boxes. I have three tool boxes, lined up to each other side by side. On the farthest right side I have my first tool box. It is an inexpensive Craftsman tool box that I have had since I was a young teenager. For years this sat next to my work bench. Whatever did not fit in this box or the drawers of my work bench was hung up on the garage walls. This tool box now holds tools that I seldom use. These tools include things like my air conditioning tools, brake tools, and engine rebuilding tools. Some tools sit in this tool box for a year or more with no use.

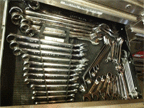

This month, I am talking about my tool box, or rather, my tool boxes. I have three tool boxes, lined up to each other side by side. On the farthest right side I have my first tool box. It is an inexpensive Craftsman tool box that I have had since I was a young teenager. For years this sat next to my work bench. Whatever did not fit in this box or the drawers of my work bench was hung up on the garage walls. This tool box now holds tools that I seldom use. These tools include things like my air conditioning tools, brake tools, and engine rebuilding tools. Some tools sit in this tool box for a year or more with no use. No toolbox should be without sockets too. I have both 6 point and 12 point sockets, in both standard and deep socket. I have these socket sets in Metric, SAE and BSF (British Whitworth). I have these sockets in 1/4″, 3/8″ and 1/2″. All of my 1/4″ sockets have their own drawer, as do my 3/8″, 1/2″ and 3/4″ sockets.

No toolbox should be without sockets too. I have both 6 point and 12 point sockets, in both standard and deep socket. I have these socket sets in Metric, SAE and BSF (British Whitworth). I have these sockets in 1/4″, 3/8″ and 1/2″. All of my 1/4″ sockets have their own drawer, as do my 3/8″, 1/2″ and 3/4″ sockets. I have an assortment of specialty tools that I have purchased from auto parts stores, these were usually tools that I needed to finish a project.

I have an assortment of specialty tools that I have purchased from auto parts stores, these were usually tools that I needed to finish a project.

Trailer tires are quite different from traditional passenger car and truck tires. Trailer tires are not designed for either tractive effort or steering adhesion. The tread design is not optimized for ride comfort or noise reduction. Most importantly, the side walls are designed to reduce trailer sway and provide optimum control.

Trailer tires are quite different from traditional passenger car and truck tires. Trailer tires are not designed for either tractive effort or steering adhesion. The tread design is not optimized for ride comfort or noise reduction. Most importantly, the side walls are designed to reduce trailer sway and provide optimum control. This summer I decided it was time to figure out what was wrong with the car and fix it. I found a sunken carburetor float in the rear carburetor, a torn diaphragm in the front carburetor, a bad fuel pump and a dead battery. Once I got these issues sorted out, I began to tune the car and get it running again. It soon became apparent that there was an issue with the brakes. Both front and rear brakes were dragging, and the pedal did not feel right. I know that the brake fluid has not been changed in at least 15 years. When I removed the caps to inspect the brake fluid, I found a nasty surprise. We all know that brake fluid absorbs moisture. Due to some spring flooding this year, the building the car was stored in, had several inches of standing water on the floor of the garage.

This summer I decided it was time to figure out what was wrong with the car and fix it. I found a sunken carburetor float in the rear carburetor, a torn diaphragm in the front carburetor, a bad fuel pump and a dead battery. Once I got these issues sorted out, I began to tune the car and get it running again. It soon became apparent that there was an issue with the brakes. Both front and rear brakes were dragging, and the pedal did not feel right. I know that the brake fluid has not been changed in at least 15 years. When I removed the caps to inspect the brake fluid, I found a nasty surprise. We all know that brake fluid absorbs moisture. Due to some spring flooding this year, the building the car was stored in, had several inches of standing water on the floor of the garage.