By now you have probably been made aware of Ethanol, and the associated problems with it. We have been forced to buy E-10 for a few years now. E-10 is 10% corn based alcohol. E-10 is about 15-20% less efficient than conventional gasoline, resulting in a significant decrease in the miles per gallon. The alcohol in Ethanol is hydroscopic, it absorbs moisture. Once the alcohol absorbs all the moisture it can from the air, it becomes saturated, and the water falls out of suspension. This is called “phase separation.” When this happens, the fuel is useless and must be removed and discarded. This is of particular concern with older cars that have gas tanks vented to the atmosphere. The “shelf life” of Ethanol exposed to the atmosphere is only 3-6 months.

Although Ethanol has less energy in it than conventional gasoline, it actually burns hotter. This is a problem. Modern cars are now burning valves. This problem virtually disappeared with unleaded gas and hardened valves in the 1970s. Imagine my shock when my 2000 Chrysler minivan burned an exhaust valve.

This nasty brew is also very corrosive. Ethanol is a strong solvent. It will rot and destroy rubber components. Many fuel lines, carburetor gaskets, fuel pump diaphragms and gas tank sealers are not comparable with Ethanol. Remember that fuel tank sealer you used when you restored your car? That sealer is probably not Ethanol compatible. Rubber components will rot and be destroyed from the inside out (note picture to right). This damage will not be visible, until the part fails and begins to leak. A fuel line may look fine on the outside, but be rotted on the inside. Ethanol will combine with the dissolved rubber components, forming a gelatinous gunk and gum up the carburetor. Ethanol will also remove paint. Remember the moisture that is being held in suspension in Ethanol? Another nasty consequence of Ethanol is that water being held in suspension will rust metal components very quickly.

Ethanol is ok to use in Flex-Fuel vehicles. If your vehicle is a Flex-Fuel vehicle, you have nothing to worry about. How do you know if you have a Flex-Fuel vehicle? Your vehicle will say “Flex-Fuel on the side, have a yellow gas cap, or will have such identifying information in the owners manual.

How can this situation get any worse? Wait! It does get much worse! The government has decided to up the alcohol in Ethanol another 50%. What’s worse than E-10? E-15!

The government will flat out tell you not to use the mandated E-15 in vehicles manufactured before 2001; but that it is ok to use in Vehicles manufactured AFTER 2001.

However, (according to snopes.com) “several automakers and the American Automobile Association (AAA) have disputed the EPA’s claims, maintaining that E15 could damage fuel lines and void vehicle owners’ warranties in many cars, particularly vehicles manufactured prior to 2012:

Only 12 million of the more than 240 million light-duty vehicles in the United States are approved by manufacturers to use the gasoline, according to AAA. Automotive engineering experts believe that sustained use of the gas, both in newer and older vehicles, could cause accelerated engine wear and failure, fuel-system damage and false “check engine” lights for vehicles not approved by manufacturers to use E15, according to AAA.

The EPA recommends the use of E15 only in flexible-fuel vehicles and those built in 2001 or later, but critics maintain that even if E15 is safe for most or all cars in that class, many vehicles still on the road (up to 45% in some areas) do not fall within that class, and the newness of E15 means that many drivers could end up filling their tanks with the gasoline, not knowing it’s not approved for all vehicles.

“It is clear that millions of Americans are unfamiliar with E15, which means there is a strong possibility that many may improperly fill up using this gasoline and damage their vehicle,” AAA President and CEO Robert Darbelnet said. “Bringing E15 to the market without adequate safeguards does not responsibly meet the needs of consumers.”

BMW, Chrysler, Nissan, Toyota and VW have said their warranties will not cover fuel-related claims caused by E15. Ford, Honda, Kia, Mercedes-Benz and Volvo have said E15 use will void warranties, citing potential corrosive damage to fuel lines, gaskets and other engine components.

The AAA says the sale and use of E15 should be stopped until there is more extensive testing, better pump labels to safeguard consumers and more consumer education about potential hazards.”

Fortunately, Vermont’s congressional delegation are on the right side of this issue. Peter Welch is a vocal opponent of Ethanol; senators Sanders and Leahy have voiced opposition to Ethanol. The Obama administration, however, is actively pushing for E-15.

The only Silver lining in this mess is that the overall demand for gasoline is down, so there is less of a push to go to E-15.

Please email all inquiries to: Dave

Please email all inquiries to: Dave

or snail mail

32 Turkey Hill Road

Richmond VT 05477

So, what makes water pump grease different than conventional chassis grease? Depending on the grease, it is either a grease that won’t be washed away by water, or a water soluble grease that will wash away and dissolve in water preventing a blockage in the cooling system.

So, what makes water pump grease different than conventional chassis grease? Depending on the grease, it is either a grease that won’t be washed away by water, or a water soluble grease that will wash away and dissolve in water preventing a blockage in the cooling system. Please email all inquiries to: Dave

Please email all inquiries to: Dave

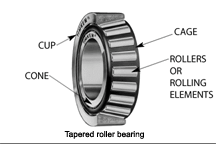

Bad wheel bearings have several tell tale signs of failure. They often make a humming, growling sound at speed. When turned by hand, they often make a “gravely” sound. There should be no axial play in the hub. Front wheel bearings that have failed will make a different sound as the steering wheel is turned. Generally, if the bearing sound goes quieter when you turn the wheel to the left, it is the right bearing, and if it gets quieter when you turn to the right, then it is the left bearing.

Bad wheel bearings have several tell tale signs of failure. They often make a humming, growling sound at speed. When turned by hand, they often make a “gravely” sound. There should be no axial play in the hub. Front wheel bearings that have failed will make a different sound as the steering wheel is turned. Generally, if the bearing sound goes quieter when you turn the wheel to the left, it is the right bearing, and if it gets quieter when you turn to the right, then it is the left bearing. To repack a wheel bearing, first the spindle or axle nut needs to be removed. Often a puller will be needed to remove the hub assembly. If the cones need to be removed, a press will come in handy for removal. The grease seals will almost certainly be destroyed upon removal. The bearings and the hub need to be cleaned and dried. Kerosene and a clean paint brush work well to clean old wheel bearing grease. Once washed clean of grease, all traces of the solvent need to be removed. Soap and hot water work well for a final clean. Traces of solvent will destroy the wheel bearing grease. Once the bearings are clean and dry, they are ready for an inspection and greasing. Inspect the bearings carefully, looks for pits, scoring, rough spots or signs of overheating. Spin the bearing and listen for the tel-tale “gravely” sound. Feel the bearing as it rotates and feel for any binding or rough rotation.

To repack a wheel bearing, first the spindle or axle nut needs to be removed. Often a puller will be needed to remove the hub assembly. If the cones need to be removed, a press will come in handy for removal. The grease seals will almost certainly be destroyed upon removal. The bearings and the hub need to be cleaned and dried. Kerosene and a clean paint brush work well to clean old wheel bearing grease. Once washed clean of grease, all traces of the solvent need to be removed. Soap and hot water work well for a final clean. Traces of solvent will destroy the wheel bearing grease. Once the bearings are clean and dry, they are ready for an inspection and greasing. Inspect the bearings carefully, looks for pits, scoring, rough spots or signs of overheating. Spin the bearing and listen for the tel-tale “gravely” sound. Feel the bearing as it rotates and feel for any binding or rough rotation. Reassemble the bearing/hub assembly. Do not fill the voids of the hub with extra grease. Once the assembly is together, tighten the spindle or axle nut. If there is a torque specification, torque to spec. If not, and it is a tapered roller bearing spindle, I tighten the nut until the bearing just starts to bind, then back off until I can install a cotter pin. You want to find the “sweet spot” where the wheel is loose, and also not binding at all. Too tight, or too loose and the bearing will soon fail. Feel the hub assembly and check for wob-ble in the bearing. Put the wheel back on and spin it a few times. Check for free noise free rotation, then check for wobble again. Place the dust cover on, and you are all set.

Reassemble the bearing/hub assembly. Do not fill the voids of the hub with extra grease. Once the assembly is together, tighten the spindle or axle nut. If there is a torque specification, torque to spec. If not, and it is a tapered roller bearing spindle, I tighten the nut until the bearing just starts to bind, then back off until I can install a cotter pin. You want to find the “sweet spot” where the wheel is loose, and also not binding at all. Too tight, or too loose and the bearing will soon fail. Feel the hub assembly and check for wob-ble in the bearing. Put the wheel back on and spin it a few times. Check for free noise free rotation, then check for wobble again. Place the dust cover on, and you are all set. I thought about this when our MG TD burned out yet another brake light switch. The replacement brake light switch lasted about 300 miles before it burned out. The replacement switch just can’t handle the amperage of the incandescent stop lights. The MG does not have a relay in the brake light circuit, or any other circuit for that matter. All the switches in the car handle the full amperage of the circuit. Of course this is true for the stop light switch too.

I thought about this when our MG TD burned out yet another brake light switch. The replacement brake light switch lasted about 300 miles before it burned out. The replacement switch just can’t handle the amperage of the incandescent stop lights. The MG does not have a relay in the brake light circuit, or any other circuit for that matter. All the switches in the car handle the full amperage of the circuit. Of course this is true for the stop light switch too.