Recently I got a question about the many different types of antifreeze available today. Specifically, what type to put in a new Honda with blue coolant. So, here it is:

Types of Coolant (Antifreeze)

Today’s coolant market is confusing. In days past all coolant was the green ethylene glycol variety, one type of coolant for every car. Now it seems that every car manufacturer has at least one color of coolant. What Type of Antifreeze Should I Use?…..All Makes and Models?…Extended Life 150,000 Miles?…..Green, Red, Yellow, Orange, Pink, Blue? There are a lot of choices of different automotive coolants today. So, which one should you use in your car? You should use what your car was made to have. However, sometimes it may be difficult to decipher what the original equipment manufacturer (OEM) used, especially if you purchased your car used.

Basically, there are three basic types of automotive coolant: Inorganic Acid Technology (IAT), Organic Acid Technology (OAT), and Hybrid Organic Acid Technology (HOAT).

IAT coolants are the “traditional green” variety used in virtually all American vehicles from the late 1920s to the mid to late 1990s. Like all antifreeze, it is naturally clear; its color comes from dye. Unlike the other types of antifreeze, it uses silicate and phosphate corrosion inhibitors to protect the metal parts of the engine and cooling system. However, these inhibitors wear out quickly, so IAT type coolants need to be flushed every two years or 30,000 miles. OAT coolants typically do not use silicate and phosphate corrosion inhibitors. Different manufacturers use different chemical additives to battle rust and corrosion, and they all dye their coolants different colors. GM’s ubiquitous DEX-COOL coolant is an OAT antifreeze dyed orange. Toyota, Volkswagen, and Audi all use their own formulas that happen to be dyed pink. Honda uses a dark green (blue) dye. OAT coolants have longer service lives than IAT coolants, needing to be flushed every 5 years or 150,000 miles. HOAT coolants use different additives than OAT, but also use some silicate to protect aluminum surfaces. Modern Ford, Chrysler, and most European vehicles use their own HOAT coolant formulas. Ford’s is dyed yellow and Chrysler’s is orange (not to be confused with DEX-COOL). Both use the marketing name of GO-5. HOAT coolant has the same service interval as OAT (5 years or 150,000 miles).

Summary:

- IAT – Used in early to mid-late 90’s Domestic vehicles…….This type is good for our antique cars

- OAT – Used in late 90’s GM and most Asian vehicles

- HOAT – Used in 2000’s Fords, Chryslers, and most European vehicles.

Although you can mix coolant types without harm, it is highly recommended against. If you mix an OAT or HOAT with an IAT, you will lose the extended service life of the OAT or HOAT coolant. Some people say that if you mix these types of coolant it can result in the coolant gelling, but if you keep your cooling system well maintained, this should not be a problem.

And finally, what about the “Universal, All Makes, All Models” coolant you see stuffing store shelves? Basically, those are OAT DEX-COOL clones. I would personally steer well clear of them unless your vehicle is de-signed for OAT coolant. You should always check your owners manual, and make sure the coolant you add is the same type of coolant your car requires.

Thanks to “how-to-matthew” for information contained in this article.

Please email all inquiries to: Dave

Please email all inquiries to: Dave

or snail mail

32 Turkey Hill Road

Richmond VT 05477

Please email all inquiries to: Dave

Please email all inquiries to: Dave

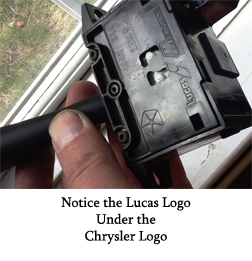

Absent any questions this month, I’ll tell the tale of a recent repair to my Chrysler minivan. I have had problems with the Body Control Module for the past few years. The BCM is the “brain” of the vehicle, and it’s function is the control of all things electrical in the vehicle. This part is vehicle specific, and stores all the vehicle data, such as the mileage on the odometer and the Vehicle Identification Number.

Absent any questions this month, I’ll tell the tale of a recent repair to my Chrysler minivan. I have had problems with the Body Control Module for the past few years. The BCM is the “brain” of the vehicle, and it’s function is the control of all things electrical in the vehicle. This part is vehicle specific, and stores all the vehicle data, such as the mileage on the odometer and the Vehicle Identification Number. Brake fluid needs to be changed every two to three years, or replaced with DOT 5 (Silicone) fluid. Failure to do so will result in low boiling temperatures and seizing pistons in calipers and wheel cylinders, resulting in brake failure.

Brake fluid needs to be changed every two to three years, or replaced with DOT 5 (Silicone) fluid. Failure to do so will result in low boiling temperatures and seizing pistons in calipers and wheel cylinders, resulting in brake failure. Notice this head gasket failure from a 2L Saab engine. The gasket literally corroded away. A very expensive repair that could have been avoided with some simple and inexpensive preventative maintenance.

Notice this head gasket failure from a 2L Saab engine. The gasket literally corroded away. A very expensive repair that could have been avoided with some simple and inexpensive preventative maintenance. So if it has been three, five, or even ten or more years since you have changed your coolant, you may want to put this chore on your to do list before your pride and joy looked like these pictures. Certain Porsche, Volkswagen and Franklin owners need not worry.

So if it has been three, five, or even ten or more years since you have changed your coolant, you may want to put this chore on your to do list before your pride and joy looked like these pictures. Certain Porsche, Volkswagen and Franklin owners need not worry.