One of my coworkers, when I was in the auto industry, jokingly called automatic transmissions “automagic” transmissions. At the time when they first came out, I imagine they did seem a little like magic — no clutch, no gearshift, and the car just did it all itself. There was no actual magic involved, just some impressive engineering. This article will be an attempt to explain some of the basics of how they work.

The main components of any automatic transmission are the torque converter, the planetary gearset(s), clutches/bands, and a control system.

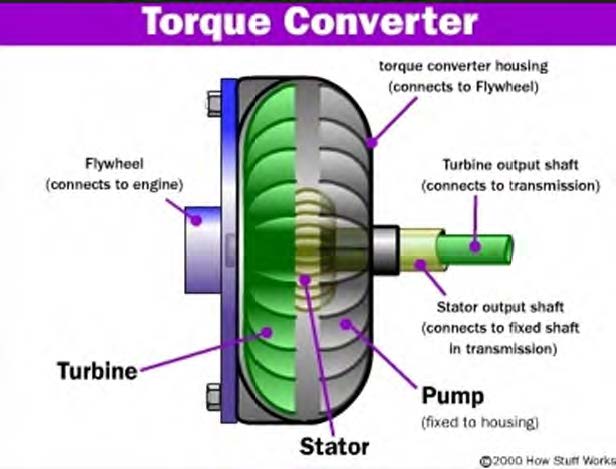

The torque converter is a fluid coupler that is functionally analogous to the clutch for a manual transmission. This is what allows engine torque to be reduced so that shifting can occur and completely removes drive torque when you are in neutral or park. The torque converter can be thought of as two fans – one connected to the engine and one to the transmission. When the “fan” connected to the engine spins fast enough, the fluid it is moving causes the other fan to rotate. This is referred to as the “stall speed” of the converter and it’s where you can feel the car just start to move as you push the accelerator. It’s a little more complicated than that, but that’s the basic idea.

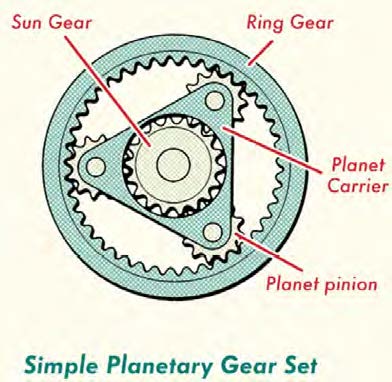

The real heart and soul of an automatic transmission is the planetary gear set. This arrangement of gears can provide speed reduction, speed increase, or reverse with speed reduction all with a single gear set depending on what component is driven, which is held stationary, and which is the output. In an automatic transmission, these are changed on the fly by a series of hydraulically actuated bands and clutches (in the Ford Model T, this was done manually with pedals actuating bands). The table below shows the combinations relevant to a simple automatic transmission like the original Hydramatic Powerglide.

| Component driven | Stationary Component | Output Component | Result |

| Sun Gear | Ring Gear | Planetary Carrier | Gear reduction |

| Sun Gear | Planetary Carrier | Ring Gear | Reverse w/ reduction |

| Sun Gear | N/A | Input locked to output | No reduction (1:1) |

I won’t get into detail on the arrangement of clutches and bands. For purposes of a brief overview, it’s sufficient to know that they hold and release components of the planetary gearsets to achieve different gear reductions (and reverse).

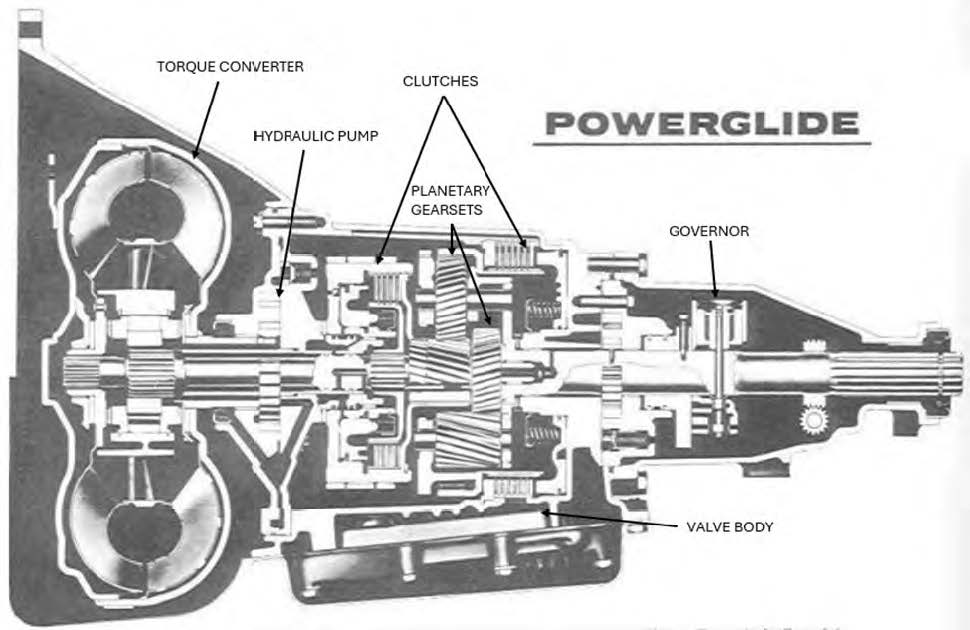

The control system for an automatic transmission consists of a pump that provides hydraulic pressure, a series of valves and pistons to actuate clutches and bands, and some means of sensing speeds and pressures within the system. In most transmissions, the pressure pump is located in front and driven by the input so that pressure is always there.

In older transmissions, speed sensing was done by a mechanical governor that activated at some fixed speed and caused the transmission to shift up beyond that the controls were achieved by a component called the “valve body” that consists of a pretty amazing hydraulic circuit (it literally looks like a circuit board, but it’s all precise fluids channels and check valves). In modern transmission, all of this control is done by electronic sensors and computer controls.

A cross section of the Powerglide transmission is shown here to give a sense of how things are arranged.

The end result of all of this is a transmission that requires no skill to operate, can shift under power and faster than a manual (which is why they are preferred for drag racing), and are easier to integrate into a vehicle (no need for a clutch pedal, no floor penetration for the shifter). Quite an advancement!

Having said all of this, I still like my manuals better!

Leave a Reply