In my last article, I wrote up the basics of the automatic transmission. One of the key components that I talked about was the planetary (or epicyclic) gearset, and in this article I will get into a little more detail of their history and versatility.

First off, why are they called “planetary” gearsets? According to Wikipedia, it’s because they were originally used by the ancient Greeks to predict the motion of planets, not necessarily to do mechanical work. This also explains some of the naming of the subcomponents (sun gear and planet gears). In modern times we understand that they are an extraordinarily versatile and efficient means of providing gear reduction and/or reversing.

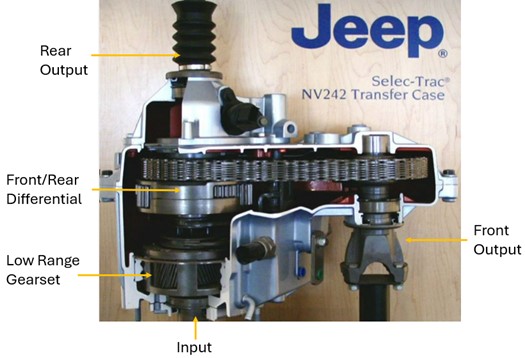

As I previously mentioned, the output of a single planetary set can be changed from direct drive to gear reduction, to reverse with reduction simply by changing what is driven, what is held stationary, and what is the output. All of those arrangements have one of the components held stationary; it is also possible to use a planetary set as a differential if none of the components are grounded. This is sometimes called a “pancake” differential. An example of this from my former job is the NV242 transfer case (it was used in some Jeeps as well as the original H1 Humvees). The cutaway image at right is a good example of planetaries being used both for gear reduction as well as a front-to-rear differential.

To give you some idea of the size and weight benefits of using planetary gearsets, the NV242 weighed around 80 lbs. Its predecessor with equivalent functionality was the NP203 which used non-planetary gear reduction and a bevel gear differential (like you would find in a rear axle). The NP203 weighed 170 lbs!

Another advantage of the pancake differential is the ability to change the bias of the differential (a standard differential has a 50/50 torque split, meaning it wants to send the same amount of torque to both outputs). If memory serves, the NV242 had closer to a 60/40 split biased toward the front output; this causes the vehicle to be more stable in slippery conditions since the front end is pulling it straight.

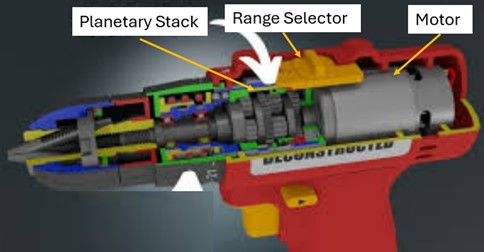

While the weight reduction I mentioned above is impressive, another area where planetaries have made a huge impact is in the world of hand tools. Aside from battery technology, the other development that has made cordless power tools so ubiquitous is the use of small, stacked planetary gearsets to achieve very highspeed reduction in a very small, light package. A single planetary can easily give 4:1 or higher reductions. If you stack them in series (the output of one is the input to the next one, you can quickly get to reductions of 100:1 or more. This allows the use of a small, very high-speed electric motor (maybe 10,000 rpm) geared down by roughly 100:1. The result is small, light and yet very powerful. Additionally, since the planetaries are in series, it is possible to lock some out and have multiple speeds, as can be seen in the image to the left.

It’s pretty amazing to think how a relatively simple arrangement of gears has impacted our lives in so many areas. And to think it started out as a way to predict where planets would be in the sky!

Leave a Reply