This month, I am talking about my tool box, or rather, my tool boxes. I have three tool boxes, lined up to each other side by side. On the farthest right side I have my first tool box. It is an inexpensive Craftsman tool box that I have had since I was a young teenager. For years this sat next to my work bench. Whatever did not fit in this box or the drawers of my work bench was hung up on the garage walls. This tool box now holds tools that I seldom use. These tools include things like my air conditioning tools, brake tools, and engine rebuilding tools. Some tools sit in this tool box for a year or more with no use.

This month, I am talking about my tool box, or rather, my tool boxes. I have three tool boxes, lined up to each other side by side. On the farthest right side I have my first tool box. It is an inexpensive Craftsman tool box that I have had since I was a young teenager. For years this sat next to my work bench. Whatever did not fit in this box or the drawers of my work bench was hung up on the garage walls. This tool box now holds tools that I seldom use. These tools include things like my air conditioning tools, brake tools, and engine rebuilding tools. Some tools sit in this tool box for a year or more with no use.

The tool box in the middle is a better grade Craftsman tool box that was a hand-me-down from my father-in-law. This tool box holds tools like hammers, files, my 3/4″ socket set, clamps, pliers, drill bits, tin snips, my tap and die set and measuring equipment.

The tool box on the far left is a professional grade stainless steel toolbox. This tool box came from Costco about 15 years ago. This tool box has the tools I use the most, tools like wrenches, ratchets, spring compressors, pullers, dwell meter, tune up tools, and test equipment. The tools that are used the most are in the upper drawers, with lesser used tools in the drawers below. I have mounted badges from cars long gone to my tool box as a way to personalize it.

I am rather partial to quality hand tools. These are the tools that are part of the physical connection between us and our car hobby. The wrenches we hold in our hand to work on our car are a tangible connection to our vehicle, something we spend a great deal of time physically holding in our hands.

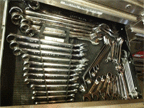

![]() I purchased my first set of fully polished wrenches almost 20 years ago. These wrenches are very comfortable to hold, and very rewarding to use. The box end of the wrench does not simply grab the corners of nuts and bolts, but, rather also grabs them on the flats too. In addition to being very comfortable to use, these wrenches grip fasteners very well, greatly reducing the possibility of the wrench slipping and stripping the head of the fastener. I have been told that Snap-on pioneered and patented this idea, but the patents have expired. The box end of these wrenches is very small, allowing them to fit in to tight places. These wrenches are also very light weight, making them much easier to use. When I finish with a job, I always wipe my tools down with a rag before I put them away. Traditional drop forged satin finished wrenches are very hard to keep clean. Fully polished wrenches come clean with a quick wipe. Sometimes it is necessary to give them a quick wipe with a rag dipped in Kerosene. Either way, they come clean easily.

I purchased my first set of fully polished wrenches almost 20 years ago. These wrenches are very comfortable to hold, and very rewarding to use. The box end of the wrench does not simply grab the corners of nuts and bolts, but, rather also grabs them on the flats too. In addition to being very comfortable to use, these wrenches grip fasteners very well, greatly reducing the possibility of the wrench slipping and stripping the head of the fastener. I have been told that Snap-on pioneered and patented this idea, but the patents have expired. The box end of these wrenches is very small, allowing them to fit in to tight places. These wrenches are also very light weight, making them much easier to use. When I finish with a job, I always wipe my tools down with a rag before I put them away. Traditional drop forged satin finished wrenches are very hard to keep clean. Fully polished wrenches come clean with a quick wipe. Sometimes it is necessary to give them a quick wipe with a rag dipped in Kerosene. Either way, they come clean easily.

Having the right wrench is important. Sometimes only a short “stubby” wrench will fit; other times an off set wrench will do the trick. Sometimes there is no room for a socket wrench to fit, but a ratchet wrench will fit just fine. Working on tubing is almost impossible without a quality flare wrench. Soft fittings made out of aluminum or brass are very easy to strip. All of my SAE wrenches have their own drawer, as do all of my Metric and BSF (Whitworth) wrenches.

No toolbox should be without sockets too. I have both 6 point and 12 point sockets, in both standard and deep socket. I have these socket sets in Metric, SAE and BSF (British Whitworth). I have these sockets in 1/4″, 3/8″ and 1/2″. All of my 1/4″ sockets have their own drawer, as do my 3/8″, 1/2″ and 3/4″ sockets.

No toolbox should be without sockets too. I have both 6 point and 12 point sockets, in both standard and deep socket. I have these socket sets in Metric, SAE and BSF (British Whitworth). I have these sockets in 1/4″, 3/8″ and 1/2″. All of my 1/4″ sockets have their own drawer, as do my 3/8″, 1/2″ and 3/4″ sockets.

I also have an assortment of ratchets and extensions too. Wobble extensions are a necessity for hard to reach nuts and bolts. I have some dedicated pipes, or “cheater bars” too. I have a two foot pipe in my 1/2″ socket drawer, and a 5′ pipe next to the tool box.

Most of my hand tools are in cradles, so in addition to keeping them well organized I can pick them up and carry them over to whatever I am working on. This is very handy with both wrenches and sockets.

Most of my hand tools are Craftsman “professional” tools I have purchased significantly marked down on sale at Sears. Most of my BSF tools were made in India, they are very high quality but also relatively inexpensive. The tools I use less frequently are very inexpensive. I can’t justify (or afford) top quality tools that I only use a couple of times a year. My A/C vacuum pump is a $10 Harbor Freight pump. I bought a carbon pile battery load tester from Harbor Freight about 10 years ago. It looks a lot like the $500 Snap-On tool, but it only cost $30 with a coupon. It probably does not work as well as the Snap-on, but for the few times a year I use it works quite well.

I have an assortment of specialty tools that I have purchased from auto parts stores, these were usually tools that I needed to finish a project.

I have an assortment of specialty tools that I have purchased from auto parts stores, these were usually tools that I needed to finish a project.

The most important part of tool ownership is taking care of them. They can not work if they can’t be found easily. If they are not properly taken care of, they will not perform for you when you need them. If I need a hand in the shop, I can ask someone to get a tool for me. I know right where it is, and can give quick instructions to someone to retrieve it for me.

I never use a cheater pipe on a high quality ratchet. I have standard drop forged Craftsman ratchets for those jobs. If it breaks, it gets fixed or replaced for free. If it gets a ding in it, it won’t ruin my day. I never hit a high quality wrench with a hammer, I have a Harbor Freight set I use when I need to whack a wrench with a hammer.

I spend a lot of time with my tools, and enjoy using them. If properly taken care of, your tools will take good care of you and your projects.

Please email all inquiries to: Dave

Please email all inquiries to: Dave

or snail mail

32 Turkey Hill Road

Richmond VT 05477

Leave a Reply