Progress is great. When a product appears on the market that increases the safety, service life, ease of maintenance, and the performance of our cars, it is a good thing. Perhaps you may have noticed there is a new type of brake line on the market.

A little history- Before WWII, many manufacturers used copper brake lines. Copper is both easy to form, and resists corrosion well. Unfortunately, copper is also prone to cracking. Shortly before the war, there was a transition to steel tubing for brake lines. Steel did not have the cracking problem of copper, but it did corrode. Steel brake lines would often fail after only a few years of use. The options to prolong the life of steel brake lines included many types of coatings to protect against corrosion.

Steel brake lines failing due to corrosion was not acceptable to safety obsessed Sweden. Both Saab and Volvo experimented with epoxy coatings, anodized steel and various other coatings to protect the brake lines. Volvo introduced a new type of brake line in 1976. This new brake line consisted of 89% Copper, 1% Iron, and 10% Nickel. This alloy proved to be durable with the corrosion resistance of copper and the crack resistance of steel.

Years ago when doing repair work I found steel brake lines would only last a few years before they would fail due to corrosion. I used anodized brake line exclusively for the last ten years or so. This anodized line lasts much longer than bare steel line.

Copper-Nickel tubing is much easier to form than steel, resists kinking and virtually will not corrode. I have found that a tubing bender is useful, but not necessary to bend Copper-Nickel tubing.

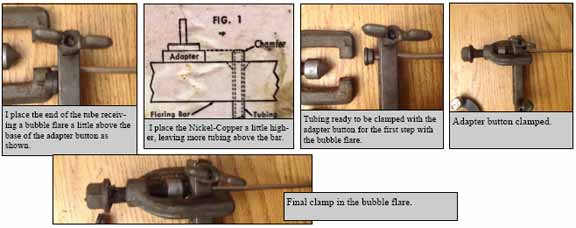

Cutting and bubble flaring Copper-Nickel tubing is actually quite easy. As with steel tubing, it is imperative to start with a nice, clean square cut. Nothing but a sharp tubing cutter will do.

Make sure there are no burrs on the end of the tube, and that you have a nice clean cut. Like steel, it may be necessary to dress the cut tube with a fine file before flaring. Unlike steel, I have found it is NOT necessary to chamfer the fresh cut end of the tube before using the flaring tool.

Because the Copper-Nickel is softer than steel, I found I have to be more gentle with a bubble flare tool. It takes far less effort to drive the mandrel in to the tube, and to pinch the final flare. I also found that it works better to use a tad more material for the flare than with steel. When installing and tightening the flare nuts, I found it takes less effort to tighten the fittings with no leaks. The Copper-Nickel tubing has more “squish” than steel.

I recently replaced all of the brake lines on my Chrysler minivan. With the ABS pump, proportioning valve, duel circuits and the many transitions to rubber hose and back to metal, there were many individual lines to form and many fittings to flare. The Copper-Nickel was far easier to work with than steel would have been. When I finished the job, there were no leaks.

Copper-Nickel brake line is stocked at most auto parts stores, and the price is comparable to anodized steel tubing. Do yourself a favor and try some the next time you have to replace a brake line. You won’t be disappointed!

Please email all inquiries to: Dave

Please email all inquiries to: Dave

or snail mail

32 Turkey Hill Road

Richmond VT 05477

Leave a Reply