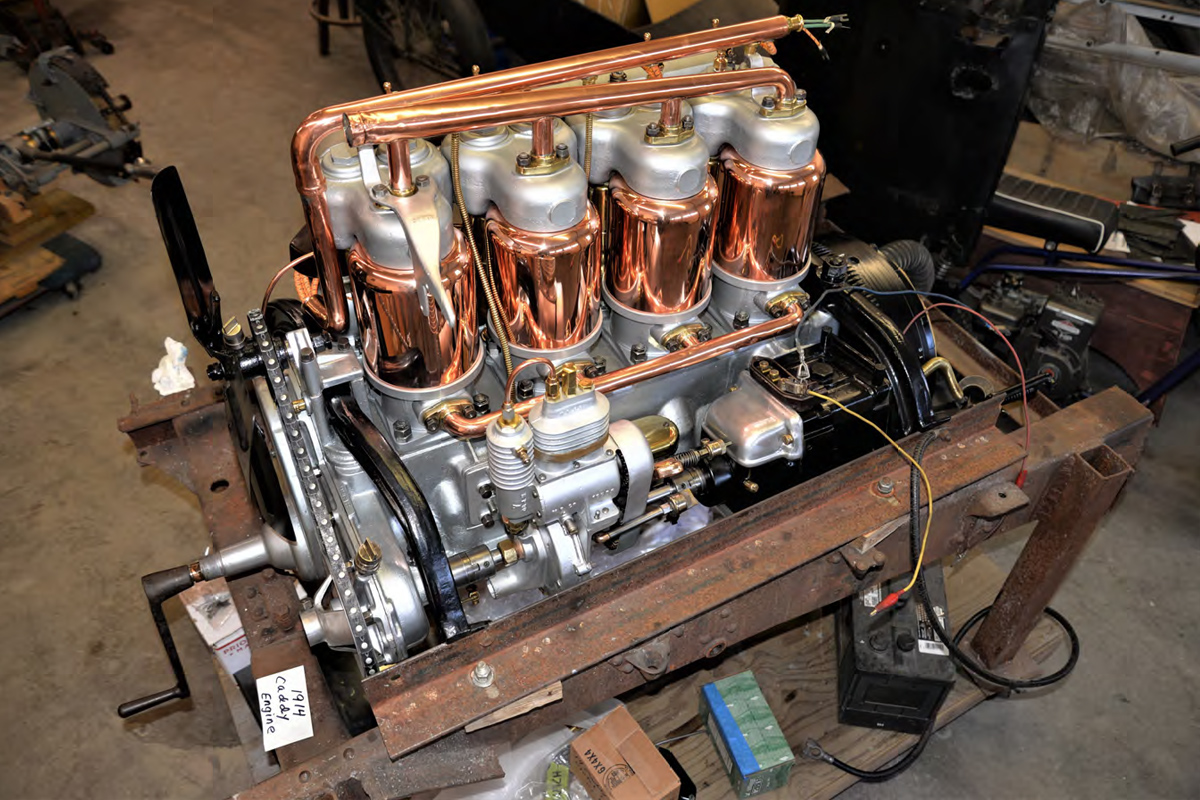

“It is way too nice to put in my car, I am going to make a coffee table out of it…..” The words of engine owner, Bill Fagan, after seeing Fred Gonet’s beautiful work. Fred’s business is G&G Restoration of Proctorsville, Vermont. Many years are needed to reach this level of restoration ability and Fred has them.

According to “The American Cars” standard catalog, Cadillac’s engine numbers ranged from 91005 to 99999 in 1914. Does this mean Cadillac made 8,994 of these pieces of art that year? Bill Fagan’s engine number is 99618.

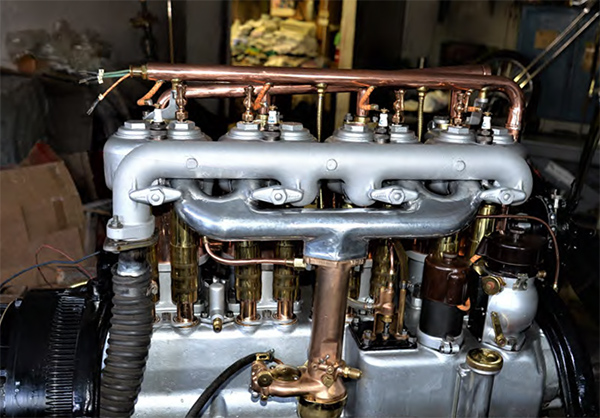

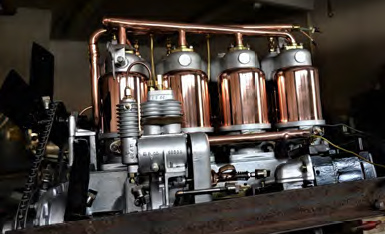

The engine is an in-line, Vertical L-head engine with cast iron cylinders and copper water jackets. Displacement is 366 cu. inches and produces 40 to 50 brake HP. The publication also notes that 1914 was the last 4-cylinder engine that Cadillac produced in the next 67 years. The company went to the 70 HP V-8 in 1915.

Bill Fagan’s plan is to take the car to Fred Gonet’s Proctorsville shop in March to have the engine installed. Here is Bill’s “barn find” story…

A friend of mine in NH has the exact same Phaeton, being the rarer Sport model 4 passenger body, as opposed to the larger 5 passenger body with 2 jump seats in the back.

The story is, my friend was working with the Boy Scouts on a Soap Box Derby with another guy, got to talking about old cars and the guy said his father died and left him a very low mileage ‘14 Cadillac. It was in the barn and had not run since the mid ‘50’s when they tried to start it and burned up the rear main bearing. The father had bought the car in the late ‘30’s from the original owner in Maine and drove it all through the ‘40’s until the early ‘50’s when he got involved in Sports Cars, so the Caddy was parked in the barn and there it languished until 2006 when my friend struck a deal for it and some parts.

On a Brass Era Frostbite Tour in Mass. a few days later, my friend told me he had just run across this “barn find” ‘14 Caddy, and was I interested? Needless to say I was and drove to his place in NH the day after the tour and made the deal. Because the car sat in the barn with a damp floor, the fenders, splash aprons and wheel rims were quite rusty and had to be repainted. The body and upholstery are original and in excellent condition. I’ve gone through the running gear and the frame, painted them and the wheels and Nickel plated all the bright work.

Ten years ago I had pulled the engine, dismantled it and cleaned all the parts and painted where needed. After this 10 year hiatus, I brought everything to Fred and he started to work his magic, as I tried to remember what I had and had not done! The heads had to be removed from the jugs with a special high torque tool my friend made up and Fred modified. New valves and guides had to be made down in Mass. and the heads remachined. Fred pulled the copper jackets off the jugs, pounded out the dents and buffed them. Its a very delicate operation. 100 years of rust and sediment gets trapped in there and is the cause for these copper clad jugs to overheat, a notorious Cadillac problem.

Most owners are too nervous to try and pull the copper jackets off. Fred made up a jig to hold the iron ring that holds the copper jackets in place. The ring has to be heated up with a torch and slid down over the copper jacket. You have only one chance to get it right before it cools and contacts around the base of the copper. You will inevitably damage the copper jack-et trying to get it back off if you mess up! I had gotten new Arias Aluminum Pistons made 10 years ago, but got side tracked on other projects, so everything had come to a stand still. At this juncture, I am waiting for new tires and tubes back ordered from Coker, then I can get the car to Fred and hopefully get it on the road this Summer.

Fred Gonet told about the other items that he needed to do, to get the engine ‘sorted’. Part of the engine was together but he needed to be sure all tolerances were correct, so everything was disassembled. Once the copper jackets were removed, he used heat to anneal the metal and then hammered out the dents, then smoothed and polished them to what you see in the pictures.

The old coil was unusable so he re-engineered a motorcycle coil to fit into the factory assembly.

New plug wire ends were built to factory specs, the distributor was completely gone-through, all lower end bearings were re-shimmed and the timing was setup. Interestingly, the oil pan is built with two compartments but only one has a drain plug for removing the old oil. With Fred’s “modern touch” the ’14 engine now has two drain plugs and also oil-level plugs installed for both compartments.

Surprising to many is the size of the cone-clutch. It can be seen in the picture to the left. The disc that you can see has an angled edge (cone shape) with a matching disc/cone outside of it. As the two cones are pressed together, the material in-between allows smooth vehicle movement. Originally leather was used, in this case a Kevlar material is used.

Some, have heard how drivers of these old cars have felt a weird jump while driving down the highway. When they look back “there is a snake in the middle of the road!”

The “snake” is the leather material that was kicked out by an unhappy automobile.

1 thought on “1914 Cadillac Engine”