Robert C. Hupp, who had worked for Olds, Ford and Regal, introduced his own car in Detroit in 1909. Called the Model 20, it was quite a success in the lower price class. As a promotional stunt and right off the assembly line, November 10, 1910, a Hupmobile left on a 48,600 mile around the world trip to 26 different countries, returning on January 24, 1912.

Robert C. Hupp, who had worked for Olds, Ford and Regal, introduced his own car in Detroit in 1909. Called the Model 20, it was quite a success in the lower price class. As a promotional stunt and right off the assembly line, November 10, 1910, a Hupmobile left on a 48,600 mile around the world trip to 26 different countries, returning on January 24, 1912.

In the meantime, Robert Hupp left the company in September 1911 following a dispute within the company. As Ranson Eli Olds did, when he left Oldsmobile and established REO (his initials) Hupp established R.C.H. (his initials) Automobile Company, but was not very successful.

Hupmobile did quite well through the teens and twenties with 1928 sales of 65,862. However, sales fell to 50,579 in 1929 (when over 100,000 was expected) and with the Great Depression Hupp was in trouble, as were many other automobile companies. But Hupmobile still had a couple of bright spots ahead, if not in sales and the bottom line, certainly in styling. In 1932 Hupp came out with their “form fitting” fenders (also referred to as the cycle-fendered Hupps) as well as chrome-plated wheel discs. This car was designed by industrial designer Raymond Loewy and was extremely handsome.

Raymond Loewy is probably most famous for his design work for Studebaker. Beginning in 1938, he and his team designed several notable Studebakers including the 1953-54 Starlight Coupe and Starliner Hardtop, the 1955 Speedster and the Hawk models beginning in 1956. Later in 1963, Loewy was responsible for the design of the Studebaker Avanti.

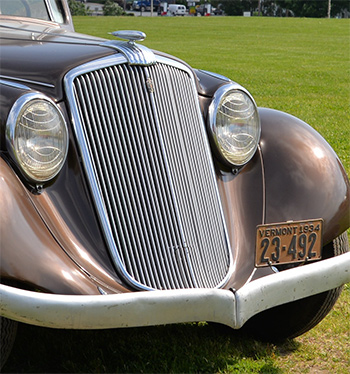

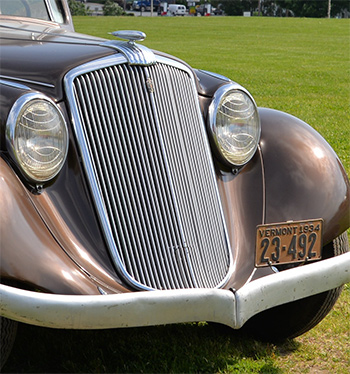

Also designed by Loewy were the Aerodynamic Hupmobiles introduced in 1934. In terms of design, these cars were several years ahead of the square, box-like designs of most four door sedans of the time. Hupmobile itself still produced these “square” models along with the sleek aerodynamic model.

The Aerodynamic Model featured a fastback design that made the 4 door appear like a 2 door sedan with the spare tire and cover molded into the sloping trunk lid. Could this have been the inspiration for the continental kit of the 50’s? It had a split rear window, maybe the inspiration for the ’63 Corvette coupe. It had a 3-piece windshield, an early version of the wrap-around windshield of the 50’s. It also had built in headlights which, except for the Chrysler and Desoto “Airflows” and Pierce Arrow, other cars didn’t have until 1938-41. Cadillac was one that waited until 1941.

I believe one of the problems leading to the demise of Hupmobile was the expense required to develop all the models and body styles they offered. In 1932 there were 8 different models (two 6-cyl. and six 8-cyl.) featuring from 1 to 6 body styles for each model. In 1934 there were 7 models (four 6-cyl. and three 8-cyl.) with 2 to 6 body styles in each model.

There were three 121″ wheel base 6 cyl. models in 1934: Series KK-421A (90 HP) with 6 different bodies; series K-421 (90 HP) with 4 bodies; series 421-J (93 HP) with 3 bodies.

The car I have is a Series 421-J sedan. The original owner was a gentleman from West Townsend, Vermont. My dad tried to buy the car in the ‘60s, but it wasn’t for sale. Some time later it was sold to Donald Miller of Miller Construction in Windsor, Vermont. My dad bought it from him and a friend, Milton Norris, restored it – probably in the early 70’s. Milton, had recently retired from one of the machine tool shops in Springfield and did an amateur restoration including mechanical work, body work (rust) and paint. Some of the chrome was replated, but the bumpers were simply painted silver. The interior is still original. We brought it to Derby Line in the late ’80s and used it for several years touring and going to shows in Sherbrooke, Que., Enosburg, Newport and other local events. It hasn’t been used for several years now but deserves to be back on the road again with a better paint job and chrome bumpers!!

The car I have is a Series 421-J sedan. The original owner was a gentleman from West Townsend, Vermont. My dad tried to buy the car in the ‘60s, but it wasn’t for sale. Some time later it was sold to Donald Miller of Miller Construction in Windsor, Vermont. My dad bought it from him and a friend, Milton Norris, restored it – probably in the early 70’s. Milton, had recently retired from one of the machine tool shops in Springfield and did an amateur restoration including mechanical work, body work (rust) and paint. Some of the chrome was replated, but the bumpers were simply painted silver. The interior is still original. We brought it to Derby Line in the late ’80s and used it for several years touring and going to shows in Sherbrooke, Que., Enosburg, Newport and other local events. It hasn’t been used for several years now but deserves to be back on the road again with a better paint job and chrome bumpers!!

I’ve had comments on the car from: “that’s the ugliest car I’ve ever seen” to “Wow! What awesome styling”. I guess beauty is in the eye of the beholder. The design was deemed good enough to get our Hupp recognition for “Best Original Design” at the “Art of the Car” themed car show at Shelburne Museum in 2016. Good Job, Mr. Loewy!

As for the fate of the Hupmobile, it was all downhill. There was never a 1937 model introduced, but a few cars were built from left over 1936 parts. In 1938, for $45,000, Hupmobile purchased the dies, tools, etc. that were used for the defunct 810/812 Cord hoping this could be their salvation.

The Franklin Company had sold about 43,000 cars by 1919 and had the process fairly well perfected by then. They were using 6 cylinder engines in 1906 for some of their models and by 1914 all Franklins had six cylinder engines. Managing the air flow was important in these air cooled vehicles and until 1922 all that was required was a fan between the engine and the transmission to help “pull” the air through. As the horse power increased they moved the fan to the front of the engine and continued to use the cylinder fins to force air down past the hot cylinders, this was called a “down-drafter”. As the 6 cylinder engine power grew, from 24 HP to over 100HP, the company changed again in 1930, to keeping the fan in the front but now forcing air “across” the engine thus calling it a side drafter. A much more efficient way to keep the engine cool.

It appears George and Eva began a family tradition with the Franklin car. Over the years they had the 1919, a 1923 sedan and two 1929s sedans. One of those 29s later was reworked into a pickup truck which also sits in David’s garage. David’s dad, Richard, added a 1930 and 1931 sedan to the family Franklin history and then David took his turn when he was 15 years old, when he purchased a used 1930 sedan for $45.00. David also bought a ’31 roadster at one point bringing the count to eight Franklins.

Richard was an engineer and loved to tweak things and make them better. While the 1919 was in his possession he added an electric fuel pump with a pressure regulator, to keep the carburetor from handling anything over one and a half pounds of fuel pressure. He also added a fuel pressure and a vacuum pressure gauge to the dash. The ignition switch has an extra position so when you engage the starter a second battery is wired in to have 12 volts. Once the engine is running, the switch is moved to the 6 volt position.

It is probably not totally unusual for an automobile to be purchased new and be in a family for ninety eight years, but Wheel Tracks did not want to miss out telling this story.

As you have read in our classifieds the 1919 is for sale. David and Cereta need to down-size and have decided to try to find a good home for the old girl, that still runs perfectly. The hope is that the car stays in the VAE family and will have many more stories to tell years from now.

How many of you will be watching for those Rutland addresses the next time you go through. Please take a picture of what is there now and send them to Wheel Tracks.

A comment on a VAE tour… “I could hear you and your ‘clutch’ behind me”

A comment on a VAE tour… “I could hear you and your ‘clutch’ behind me”

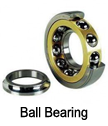

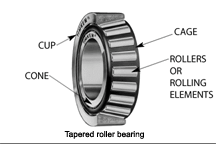

Bad wheel bearings have several tell tale signs of failure. They often make a humming, growling sound at speed. When turned by hand, they often make a “gravely” sound. There should be no axial play in the hub. Front wheel bearings that have failed will make a different sound as the steering wheel is turned. Generally, if the bearing sound goes quieter when you turn the wheel to the left, it is the right bearing, and if it gets quieter when you turn to the right, then it is the left bearing.

Bad wheel bearings have several tell tale signs of failure. They often make a humming, growling sound at speed. When turned by hand, they often make a “gravely” sound. There should be no axial play in the hub. Front wheel bearings that have failed will make a different sound as the steering wheel is turned. Generally, if the bearing sound goes quieter when you turn the wheel to the left, it is the right bearing, and if it gets quieter when you turn to the right, then it is the left bearing. To repack a wheel bearing, first the spindle or axle nut needs to be removed. Often a puller will be needed to remove the hub assembly. If the cones need to be removed, a press will come in handy for removal. The grease seals will almost certainly be destroyed upon removal. The bearings and the hub need to be cleaned and dried. Kerosene and a clean paint brush work well to clean old wheel bearing grease. Once washed clean of grease, all traces of the solvent need to be removed. Soap and hot water work well for a final clean. Traces of solvent will destroy the wheel bearing grease. Once the bearings are clean and dry, they are ready for an inspection and greasing. Inspect the bearings carefully, looks for pits, scoring, rough spots or signs of overheating. Spin the bearing and listen for the tel-tale “gravely” sound. Feel the bearing as it rotates and feel for any binding or rough rotation.

To repack a wheel bearing, first the spindle or axle nut needs to be removed. Often a puller will be needed to remove the hub assembly. If the cones need to be removed, a press will come in handy for removal. The grease seals will almost certainly be destroyed upon removal. The bearings and the hub need to be cleaned and dried. Kerosene and a clean paint brush work well to clean old wheel bearing grease. Once washed clean of grease, all traces of the solvent need to be removed. Soap and hot water work well for a final clean. Traces of solvent will destroy the wheel bearing grease. Once the bearings are clean and dry, they are ready for an inspection and greasing. Inspect the bearings carefully, looks for pits, scoring, rough spots or signs of overheating. Spin the bearing and listen for the tel-tale “gravely” sound. Feel the bearing as it rotates and feel for any binding or rough rotation. Reassemble the bearing/hub assembly. Do not fill the voids of the hub with extra grease. Once the assembly is together, tighten the spindle or axle nut. If there is a torque specification, torque to spec. If not, and it is a tapered roller bearing spindle, I tighten the nut until the bearing just starts to bind, then back off until I can install a cotter pin. You want to find the “sweet spot” where the wheel is loose, and also not binding at all. Too tight, or too loose and the bearing will soon fail. Feel the hub assembly and check for wob-ble in the bearing. Put the wheel back on and spin it a few times. Check for free noise free rotation, then check for wobble again. Place the dust cover on, and you are all set.

Reassemble the bearing/hub assembly. Do not fill the voids of the hub with extra grease. Once the assembly is together, tighten the spindle or axle nut. If there is a torque specification, torque to spec. If not, and it is a tapered roller bearing spindle, I tighten the nut until the bearing just starts to bind, then back off until I can install a cotter pin. You want to find the “sweet spot” where the wheel is loose, and also not binding at all. Too tight, or too loose and the bearing will soon fail. Feel the hub assembly and check for wob-ble in the bearing. Put the wheel back on and spin it a few times. Check for free noise free rotation, then check for wobble again. Place the dust cover on, and you are all set. Please email all inquiries to:

Please email all inquiries to:

Editor’s notes… Robert Craig Hupp, a former employee of Oldsmobile and Ford, found-ed the company with his brother Louis Gorham Hupp in 1908. Production began in 1909. Following disagreements with his financial backers Robert Hupp sold his stock in the Hupp Motor Car Company and established the short-lived RCH Automobile Company, later the Hupp-Yeats Electric Car Company. In 1912, Hupp would be one of two automakers pioneering the use of all-steel bodies. Hupp Motor Company continued to grow after its founder left. A new plant was purchased in 1924 as Hupp competed strongly against Ford and Chevrolet. DuBois Young became company president in 1924 moving up from vice-president of manufacturing. By 1928 sales had reached over 65,000 units. To increase production and handle the growth in sales, Hupp purchased the Chandler-Cleveland Motors Corporation (Chandler Motor Car) for its manufacturing facilities. Sales and production began to fall even before the onset of the depression in 1930. A strategy to make the Hupmobile a larger, more expensive car began with the 1925 introduction of an 8-cylinder model, followed by the discontinuance of the traditional 4-cylinder Hupmobile. While aiming for a seemingly more lucrative market segment, Hupp essentially turned its back on its established clientele. Unfortunately, the company made the same mistake that many other medium-priced carmakers were making at the same time. Namely, in an attempt to capture every possible sale, they offered many different models. With Hupmobile’s relatively low production volume, the result was that no model could be produced in sufficient quantity to keep manufacturing costs low enough to provide an operating profit.

Editor’s notes… Robert Craig Hupp, a former employee of Oldsmobile and Ford, found-ed the company with his brother Louis Gorham Hupp in 1908. Production began in 1909. Following disagreements with his financial backers Robert Hupp sold his stock in the Hupp Motor Car Company and established the short-lived RCH Automobile Company, later the Hupp-Yeats Electric Car Company. In 1912, Hupp would be one of two automakers pioneering the use of all-steel bodies. Hupp Motor Company continued to grow after its founder left. A new plant was purchased in 1924 as Hupp competed strongly against Ford and Chevrolet. DuBois Young became company president in 1924 moving up from vice-president of manufacturing. By 1928 sales had reached over 65,000 units. To increase production and handle the growth in sales, Hupp purchased the Chandler-Cleveland Motors Corporation (Chandler Motor Car) for its manufacturing facilities. Sales and production began to fall even before the onset of the depression in 1930. A strategy to make the Hupmobile a larger, more expensive car began with the 1925 introduction of an 8-cylinder model, followed by the discontinuance of the traditional 4-cylinder Hupmobile. While aiming for a seemingly more lucrative market segment, Hupp essentially turned its back on its established clientele. Unfortunately, the company made the same mistake that many other medium-priced carmakers were making at the same time. Namely, in an attempt to capture every possible sale, they offered many different models. With Hupmobile’s relatively low production volume, the result was that no model could be produced in sufficient quantity to keep manufacturing costs low enough to provide an operating profit.

Mary Jane Dexter tells the story of going to Germany with her husband Bill to pick up their new, factory fresh, VW like it was yesterday. In fact the poppy-red VW Convertible Beetle is 50 years old now and still sits in Mary Jane’s garage. Ninety one years old Mary Jane said the Beetle heads to her Colorado nephew, Russell Dent, when she decides it needs a new owner.

Mary Jane Dexter tells the story of going to Germany with her husband Bill to pick up their new, factory fresh, VW like it was yesterday. In fact the poppy-red VW Convertible Beetle is 50 years old now and still sits in Mary Jane’s garage. Ninety one years old Mary Jane said the Beetle heads to her Colorado nephew, Russell Dent, when she decides it needs a new owner. A couple of weeks ago we had an ice storm that knocked the electricity off at our place for 30 hours. While lying under a thick quilt, double shirts, socks and a wool hat on my head, it brought thoughts of our forefathers and mothers who went through the whole winter without electricity and of course, no central heat, electric blankets, heaters, lights, indoor plumbing, electric stoves, dryers – get the picture? I barely survived 30 hours and the temp outside wasn’t that bad. The house temp got to 50 but the worst part was no hot tea or coffee on demand. To top off the insult, it was almost Christmas! I was brought up with no dryer, no central heat but did have a good heat source, hot water and a great radio. What I am getting at is that I have become so “soft” in such a short time. How did they do it? Get up in the freezing cold, start a fire (not turn up the thermostat), bundle up and run to the well or river – break the ice on top and get a bucket of water. The first water hauled maybe wasn’t for you but for the animals. After chores, then you get some breakfast which might be plentiful or not depending on what you did to put up provisions in the fall. I’m sure there was-n’t any fresh fruit or great coffee. I have been trying to think of something that you cannot get year round now. Sure you may have to pay more for something ‘out of season’ but you can have it if you are willing to pay the price. Fifty years ago we were eating only what was in season at the time. We all have grandparents who had never had a banana when they were children. It boggles the mind! Now having ram-bled on about my hardships, I want to talk about all the people that make our lives so comfortable. Behind every convenience that fills most of our houses, there are many bright, hardworking people. Just think about what and who is behind getting that banana on the table and that is just one tiny thing that makes life (or Gary’s cereal) better. Right now my hat goes off to all the men and women who worked hours and hours in freezing rain and snow and cold to get my electricity back on. Some of them traveled from miles away to help the Vermont crew in our hour of need. Also, thanks to those who came to cut downed trees, branches and clear roads, lines for the electrical workers. I would add that these jobs were done in what were very dangerous situations and done round the clock and some gave up their Christmas with their families to see to it that we had a bright, warm Christmas with our families. So I would like to say a big THANK YOU to all those behind the scene that make life ‘living easy’ for me.

A couple of weeks ago we had an ice storm that knocked the electricity off at our place for 30 hours. While lying under a thick quilt, double shirts, socks and a wool hat on my head, it brought thoughts of our forefathers and mothers who went through the whole winter without electricity and of course, no central heat, electric blankets, heaters, lights, indoor plumbing, electric stoves, dryers – get the picture? I barely survived 30 hours and the temp outside wasn’t that bad. The house temp got to 50 but the worst part was no hot tea or coffee on demand. To top off the insult, it was almost Christmas! I was brought up with no dryer, no central heat but did have a good heat source, hot water and a great radio. What I am getting at is that I have become so “soft” in such a short time. How did they do it? Get up in the freezing cold, start a fire (not turn up the thermostat), bundle up and run to the well or river – break the ice on top and get a bucket of water. The first water hauled maybe wasn’t for you but for the animals. After chores, then you get some breakfast which might be plentiful or not depending on what you did to put up provisions in the fall. I’m sure there was-n’t any fresh fruit or great coffee. I have been trying to think of something that you cannot get year round now. Sure you may have to pay more for something ‘out of season’ but you can have it if you are willing to pay the price. Fifty years ago we were eating only what was in season at the time. We all have grandparents who had never had a banana when they were children. It boggles the mind! Now having ram-bled on about my hardships, I want to talk about all the people that make our lives so comfortable. Behind every convenience that fills most of our houses, there are many bright, hardworking people. Just think about what and who is behind getting that banana on the table and that is just one tiny thing that makes life (or Gary’s cereal) better. Right now my hat goes off to all the men and women who worked hours and hours in freezing rain and snow and cold to get my electricity back on. Some of them traveled from miles away to help the Vermont crew in our hour of need. Also, thanks to those who came to cut downed trees, branches and clear roads, lines for the electrical workers. I would add that these jobs were done in what were very dangerous situations and done round the clock and some gave up their Christmas with their families to see to it that we had a bright, warm Christmas with our families. So I would like to say a big THANK YOU to all those behind the scene that make life ‘living easy’ for me.

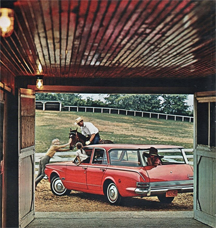

Editor’s note… To the left is a Plymouth sales ad from 1963. The ad discussed the many factory tests performed before release to the public. It read:

Editor’s note… To the left is a Plymouth sales ad from 1963. The ad discussed the many factory tests performed before release to the public. It read: