Tom Noble’s 1935 Packard Limousine

I think the best way to tell the story of the car is in two parts – first the part I know is actually true, and secondly the part that might be complete bunk…

The car is a 1935 Packard V-12 limousine that my grandfather, Bert Pulsifer, acquired sometime during the 1960s from a man named Charles Barnes. Charles was renting a house from my grandfather at the time and, having run out of money to cover rent, offered the car in lieu of of rent. My grandfather was a collector of cars and took him up on the offer. He kept the car and entered it in local parades from time to time and my Uncle Scott drove it occasionally- although I’m guessing a V-12 limousine wasn’t something anyone could afford to drive regularly even then! I do remember it sitting in the garage at Grandpa’s farm and pretending to drive it when I was little – as a kid that was the most impressive car in the world!

Perhaps to his senior prom dance!

Charlie is in junior-high today and Wheel Tracks has learned he has some dance moves to die for….

I also remember the whole family washing and waxing it in preparation for a parade. This must have been done many times because even then the paint was worn through in places. The parade I remember best – and I think it was the last time it was driven, was in 1982. The Packard had a tendency to vapor lock and I recall it did it at least twice that day. The first time was at a gas station on the way to the parade. We had stopped to fill up, but couldn’t get it to start after. Fortunately, one of Grandpa’s friends was also on his way to the parade, with his similar vintage Jaguar, and offered to push start the Packard with it. This worked and we made it to the parade.

Unfortunately, we didn’t make it THROUGH the parade. About halfway through, she vapor locked again and had to be pushed aside to let the rest of the parade go by. I’ll have to dig out the picture of me, with my Grandpa’s Mason’s ballcap on, leaning against the fender, waiting for it to cool down. My grandmother wrote on the back “Thomas guarding the Packard”. (This picture never made it to Wheel Tracks).

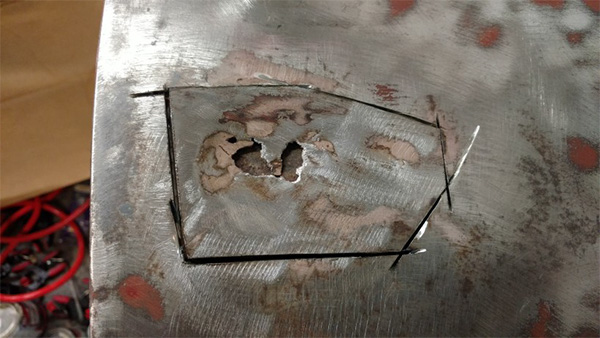

When Grandpa passed away, he left the Packard to my Uncle Scott. Uncle Scott didn’t really have a good place to keep it, and knew that I had always admired the car, so he gave it to me. I’ve had to move it a few times since then and it has remained my “someday” project that I plan to get going as time permits. The first project will be to get the gas tank cleaned/rebuilt – 30 year old gas does some bad things to the inside of a gas tank!

When Grandpa passed away, he left the Packard to my Uncle Scott. Uncle Scott didn’t really have a good place to keep it, and knew that I had always admired the car, so he gave it to me. I’ve had to move it a few times since then and it has remained my “someday” project that I plan to get going as time permits. The first project will be to get the gas tank cleaned/rebuilt – 30 year old gas does some bad things to the inside of a gas tank!

The part of the story that might be bunk, is the detail of Charles Barnes – I was always told that Charles was of the “Barnes and Noble” Barnes from Rhode Island. Apparently he was the black sheep of the family and had a girlfriend that the family did not like or approve of. The family told him he needed to leave the family estate, but that he could take any car he wanted as long as he left and didn’t come back. The car he chose, of course, was the Packard. He headed north and ended up near Plymouth, New Hampshire and began renting the house from Grandpa.

From Lester-Steele Handbook & Standard Catalog of American Cars “Packard Twelfth Series- Twelve”

*Price new….$4485.00

*Bore & stroke…3.44 X4.25

*HP….175 @3200RPM

*Weight…5900lbs

*WB– 144.25 inches

*Carburetor….Stromberg-Duplex

*Gear-ratio options,4.41, 4.06, 4.69, 5.07

*Tires…7.50X17

*3-point engine rubber suspension

*15 12-cylinder body styles offered with the limo being #835.

*Engine, 67 degree V-block, modified L.

*Displacement, 473.3 cu. in.

*Four main bearings

*Trans, selective synchromesh 3F/1R.

*Clutch, single plate, vacuum assist.

*Brakes, mechanical, vacuum assist 4W

*Options…dual sidemounts, bumper guards, radio, heater, spotlight.

*Introduced August 1934.

*V-12 model choices, series 1207wb139” & series 1208wb 144.25(the limo)

* Total factory production for all models including V8 & V12…..788

Let me first briefly explain the history of automotive paints. The early autos were painted with the same paint people had been painting carriages with for years. There was no “automotive” paint. Not paint in the traditional sense we think of when we talk about paint today. Early paint was basically linseed oil and a binder, with pigment, or crude shellac. This paint was applied with a brush and took a long time to dry. These paints were not very durable, often literally falling off the metal in a year or two. These finishes offered very little U/V protection and broke down quickly.

Let me first briefly explain the history of automotive paints. The early autos were painted with the same paint people had been painting carriages with for years. There was no “automotive” paint. Not paint in the traditional sense we think of when we talk about paint today. Early paint was basically linseed oil and a binder, with pigment, or crude shellac. This paint was applied with a brush and took a long time to dry. These paints were not very durable, often literally falling off the metal in a year or two. These finishes offered very little U/V protection and broke down quickly. Enamel paints used enamel resins. This type of paint takes much longer to dry than lacquer and actually dries in two steps. First, the enamel reducer evaporates and the paint becomes solid. Next, the resin oxidizes when it reacts to the air. This is why the new finish cannot be waxed for 30 days after application. The enamel paints dry to a hard, glossy finish and do not need the rubbing out as lacquer needs. The drying of enamel paints could be accelerated by the use of a baking oven.

Enamel paints used enamel resins. This type of paint takes much longer to dry than lacquer and actually dries in two steps. First, the enamel reducer evaporates and the paint becomes solid. Next, the resin oxidizes when it reacts to the air. This is why the new finish cannot be waxed for 30 days after application. The enamel paints dry to a hard, glossy finish and do not need the rubbing out as lacquer needs. The drying of enamel paints could be accelerated by the use of a baking oven. So, what is an old car person to do?

So, what is an old car person to do?  My interest in Corvettes probably started back in 1954 when some friends and I attended the General Motors Motorama Show in Boston where the highlight of the show, for me, was the fairly new Chevrolet Corvette display. However, it would be 21 years later that I would become the owner, of one of these cars.

My interest in Corvettes probably started back in 1954 when some friends and I attended the General Motors Motorama Show in Boston where the highlight of the show, for me, was the fairly new Chevrolet Corvette display. However, it would be 21 years later that I would become the owner, of one of these cars.

Since the very beginning the engine ran smoothly, but smoked moderately, however, eventually I detected a slight noise in the lower end. Before things got worse, I pulled the engine and transmission. It took a year to complete engine and transmission overhaul. A new radiator and rebuilding the wiper/washer, the carburetor, the distributor and the fuel pump was also done at this time.

Since the very beginning the engine ran smoothly, but smoked moderately, however, eventually I detected a slight noise in the lower end. Before things got worse, I pulled the engine and transmission. It took a year to complete engine and transmission overhaul. A new radiator and rebuilding the wiper/washer, the carburetor, the distributor and the fuel pump was also done at this time. One thing that always bothered me about this car was that the electric clock never worked. So one day I took it apart and found the manufacturer’s name. To my surprise, I was able to purchase parts (at a car show). I had the face silk-screened and reinstalled it. This was great, but it made the rest of the dash look terrible. You guessed it, out came the main dash, matter of fact, out came the whole interior, seats, carpet, belts… every-thing. This was the point where we decided that we could not reinstall a new interior unless we had the body repaired and painted. Since I didn’t really have a place to do the work or the paint and my own body was now needing some restoration of it’s own, we had no choice but to have this done by an outside source. While this was being done I totally restored the seats and recovered them. In 1966 some of the options available were seat headrests and shoulder belts. These were available through Corvette restoration parts suppliers so I added these two features.

One thing that always bothered me about this car was that the electric clock never worked. So one day I took it apart and found the manufacturer’s name. To my surprise, I was able to purchase parts (at a car show). I had the face silk-screened and reinstalled it. This was great, but it made the rest of the dash look terrible. You guessed it, out came the main dash, matter of fact, out came the whole interior, seats, carpet, belts… every-thing. This was the point where we decided that we could not reinstall a new interior unless we had the body repaired and painted. Since I didn’t really have a place to do the work or the paint and my own body was now needing some restoration of it’s own, we had no choice but to have this done by an outside source. While this was being done I totally restored the seats and recovered them. In 1966 some of the options available were seat headrests and shoulder belts. These were available through Corvette restoration parts suppliers so I added these two features.